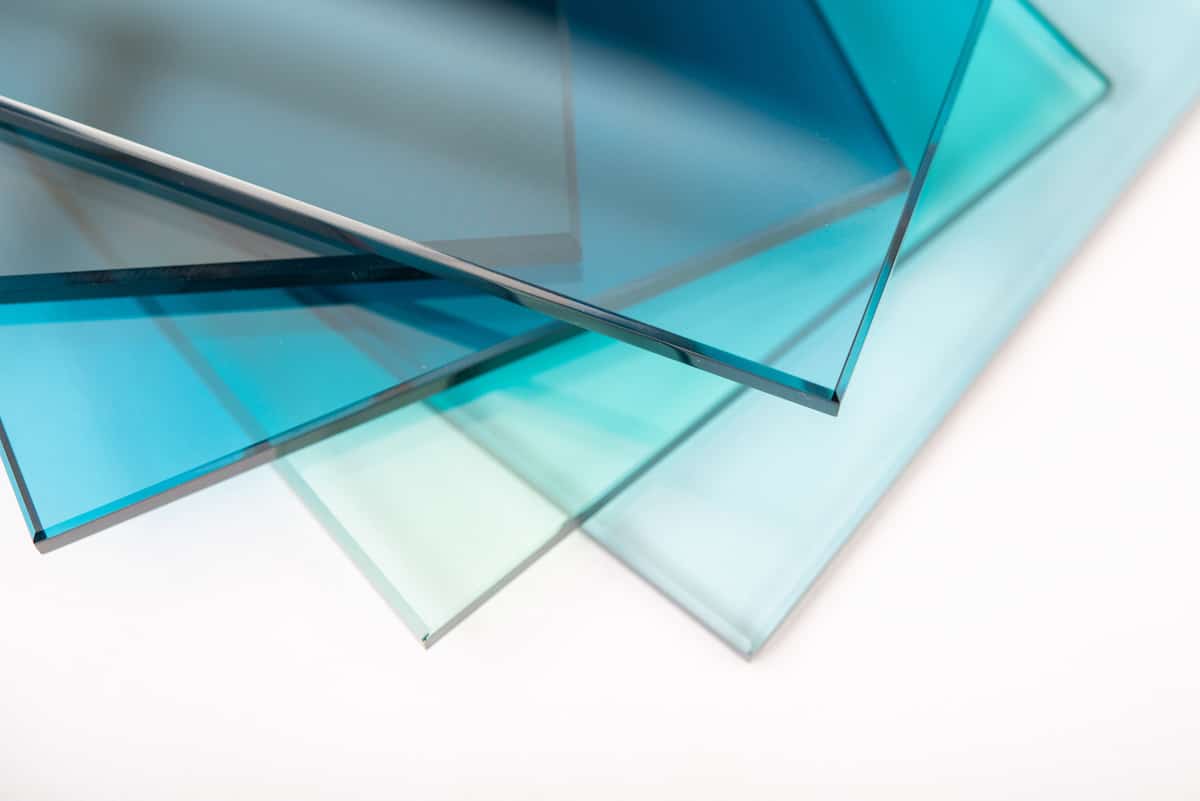

What is "vidro"? It is the Portuguese word for "glass". Glass is a hard, brittle, and transparent material made from the fusion of silica (silicon dioxide) with other materials, such as soda, lime, and potash.

Glass is an important material with a wide range of applications. It is used in windows, bottles, jars, and other containers. It is also used in the production of lenses,, and other optical devices. Glass is also used in the construction industry, where it is used to make windows, doors, and other architectural features.

The history of glass dates back to ancient times. The earliest known glass objects were made in Mesopotamia around 3500 BC. Glassmaking spread to Egypt and other parts of the Middle East, and eventually to Europe and other parts of the world.

- Historical Significance Of Fashion Icon Vincent Saint Laurent

- Casetifys Net Worth A Comprehensive Overview

The importance of glass

vidro

Vidro, the Portuguese word for "glass", encompasses a multifaceted array of properties and applications. Its transparency, hardness, brittleness, and recyclability make it a versatile material with a rich history and diverse contemporary uses.

- Transparency: Allowing light to pass through, enabling its use in windows and optical devices.

- Hardness: Resistant to scratches and damage, making it suitable for containers and architectural features.

- Brittleness: Easily breakable under stress, facilitating cutting and shaping.

- Recyclability: Capable of being reused to create new glass products, reducing resource consumption.

- Manufacturing: Produced by melting silica with other materials, shaped and cooled.

- Applications: Used in windows, bottles, lenses, construction, and various industries.

- Historical significance: Dating back to ancient Mesopotamia, with a rich cultural and technological history.

- Environmental impact: Its recyclability and durability contribute to sustainability.

These key aspects collectively highlight the importance of vidro as a material with diverse properties and extensive applications. Its transparency allows for the creation of windows and optical devices, while its hardness makes it suitable for containers and architectural features. The brittleness of vidro facilitates its cutting and shaping, enabling intricate designs and precise applications. Furthermore, its recyclability contributes to sustainability and resource conservation. Understanding these aspects provides a deeper appreciation for the significance of vidro and its multifaceted role in various industries and applications.

- The Essential Guide To Gumball 3000 Entry Requirements

- A Comprehensive Guide To Branch Banking Understanding The Role Of Branches

Transparency

Transparency, a defining characteristic of vidro, plays a significant role in its diverse applications. By allowing light to pass through, vidro becomes an essential material for windows and optical devices.

- Windows

Vidro's transparency makes it an ideal material for windows, allowing natural light to illuminate indoor spaces while providing a clear view of the outside world. This transparency enhances the livability and aesthetics of buildings, creating brighter and more inviting environments. - Optical devices

The transparency of vidro also makes it suitable for use in optical devices, such as lenses, prisms, and mirrors. These devices rely on the ability of vidro to transmit and refract light, enabling the manipulation and focusing of light for various applications, including photography, microscopy, and telecommunications. - Artistic expression

Beyond its functional applications, the transparency of vidro has also inspired artistic expression. Glass sculptures, stained-glass windows, and other art forms utilize the unique properties of vidro to create visually captivating works that play with light and color. - Scientific research

The transparency of vidro makes it a valuable material for scientific research. It allows scientists to observe and study phenomena without interference, contributing to advancements in fields such as optics, medicine, and material science.

In conclusion, the transparency of vidro underpins its use in a wide range of applications, from windows and optical devices to artistic expression and scientific research. This unique property of vidro enables the transmission of light, creating brighter spaces, facilitating optical manipulation, inspiring creativity, and supporting scientific exploration.

Hardness

The hardness of vidro, its resistance to scratches and damage, makes it an ideal material for containers and architectural features. Unlike many other materials, vidro can withstand wear and tear without losing its integrity, making it a durable and long-lasting choice.

In the context of containers, the hardness of vidro is essential for preserving the contents within. Glass bottles and jars provide a protective barrier against external elements, ensuring the quality and safety of food, beverages, and other products. The non-porous nature of vidro also prevents contamination and the absorption of flavors or odors, maintaining the purity of the contents.

In architectural applications, the hardness of vidro contributes to the structural integrity and aesthetic appeal of buildings. Glass facades, windows, and doors made of vidro can withstand harsh weather conditions, including strong winds, rain, and hail, without compromising their functionality or appearance. The scratch resistance of vidro also ensures that these architectural features maintain their pristine condition over time, enhancing the overall durability and beauty of the building.

Furthermore, the hardness of vidro makes it suitable for specialized applications, such as laboratory equipment and cookware. Glass beakers, test tubes, and other laboratory glassware can withstand the exposure to chemicals and high temperatures without cracking or breaking, ensuring accurate and reliable scientific experiments. Similarly, glass cookware, such as baking dishes and oven-safe cookware, can endure high temperatures and sudden temperature changes without shattering, making it a versatile and safe choice for culinary purposes.

In conclusion, the hardness of vidro is a crucial property that underpins its suitability for containers and architectural features. Its resistance to scratches and damage ensures the durability, safety, and aesthetic appeal of these applications, making vidro a valuable and versatile material across various industries.

Brittleness

The brittleness of vidro, its tendency to break easily under stress, is a defining characteristic that presents both challenges and opportunities in its use. Despite its inherent fragility, the brittleness of vidro also enables precise cutting and shaping, making it a versatile material for a wide range of applications.

In the context of cutting, the brittleness of vidro allows it to be easily scored and snapped along desired lines. This property is particularly advantageous in the production of glass art, where intricate designs and patterns can be created by carefully controlling the cutting process. Glassblowers also utilize the brittleness of molten vidro to shape and mold it into various forms, creating unique and delicate pieces.

Furthermore, the brittleness of vidro facilitates its use in specialized applications, such as the production of optical fibers. The ability of vidro to be drawn into thin, flexible fibers is essential for transmitting light over long distances in telecommunications and data networks. The brittleness of the glass fibers allows them to be bent and routed without breaking, enabling the creation of complex fiber optic cables.

While the brittleness of vidro can sometimes be a drawback, leading to accidental breakage, it also contributes to its unique properties and applications. By understanding and carefully managing the brittleness of vidro, designers, manufacturers, and artists can harness its potential to create innovative and functional products.

Recyclability

The recyclability of vidro, its ability to be reused to create new glass products, plays a significant role in reducing resource consumption and promoting sustainability. By utilizing recycled vidro, manufacturers can minimize the extraction of raw materials, such as silica and soda ash, and conserve natural resources.

- Environmental benefits

Recycling vidro reduces the amount of waste sent to landfills, conserving precious land space and preventing environmental pollution. Furthermore, the production of new glass products from recycled vidro requires less energy compared to using virgin materials, resulting in a lower carbon footprint.

- Economic advantages

Recycling vidro can provide economic benefits by reducing the costs associated with waste disposal and raw material extraction. Recycled vidro is often cheaper than virgin materials, making it a cost-effective option for manufacturers. Additionally, recycling programs can create employment opportunities in the waste management and manufacturing sectors.

- Quality and versatility

Recycled vidro is comparable in quality to glass produced from virgin materials, maintaining its strength, transparency, and other desirable properties. This versatility allows recycled vidro to be used in a wide range of applications, including containers, architectural features, and even high-tech products like fiber optics.

- Consumer awareness and participation

Consumer awareness and participation are crucial for successful vidro recycling programs. Educating consumers about the importance of recycling and providing convenient recycling options can significantly increase the recovery rate of vidro. Collaboration between municipalities, recycling organizations, and manufacturers is essential to establish effective recycling systems.

In conclusion, the recyclability of vidro is a key aspect that contributes to its sustainability and resource efficiency. By utilizing recycled vidro, manufacturers can reduce their environmental impact, save costs, and meet the growing demand for eco-friendly products. Promoting consumer awareness and participation, as well as establishing comprehensive recycling programs, are essential to maximize the benefits of vidro recyclability.

Manufacturing

Manufacturing processes play a crucial role in shaping the properties and applications of vidro. By melting silica with other materials, followed by shaping and cooling, manufacturers can create a diverse range of glass products with varying characteristics.

- Raw Materials and Composition

The primary raw material used in vidro manufacturing is silica, also known as silicon dioxide (SiO2). However, to obtain the desired properties, manufacturers often add other materials like soda ash (sodium carbonate), limestone (calcium carbonate), and various metal oxides. These additives influence the melting point, viscosity, and other properties of the final product.

- Melting and Shaping

The manufacturing process begins with melting the raw materials at high temperatures in a furnace. Once molten, the liquid vidro is shaped into the desired form using various techniques such as blowing, pressing, rolling, or casting. The shaping process determines the final shape and thickness of the vidro product.

- Annealing and Tempering

After shaping, the vidro undergoes a controlled cooling process called annealing. This process involves gradually cooling the vidro to relieve internal stresses and improve its strength. Tempering is another heat treatment that increases the mechanical strength and durability of vidro by introducing controlled thermal stresses.

- Quality Control and Applications

Throughout the manufacturing process, strict quality control measures are implemented to ensure the desired properties and consistency of the vidro. The final product is inspected for defects, optical clarity, and other parameters. Depending on its composition and properties, vidro finds applications in a wide range of industries, including construction, automotive, electronics, and packaging.

In summary, the manufacturing process of vidro involves melting silica with other materials, shaping the molten vidro, and subjecting it to controlled cooling and heat treatments. These steps are critical in determining the properties and applications of the final vidro product, contributing to its versatility and importance in various industries.

Applications

The diverse applications of vidro stem from its unique properties, making it an essential material in various industries. Its transparency, hardness, brittleness, and recyclability contribute to its wide-ranging uses, from everyday items to high-tech components.

- Windows and Building Construction

Vidro's transparency and durability make it an ideal material for windows, allowing natural light to enter buildings while providing protection from the elements. In construction, vidro is used in facades, skylights, and architectural features, contributing to the aesthetic appeal and energy efficiency of modern buildings.

- Containers and Packaging

The non-porous nature and transparency of vidro make it suitable for storing and preserving food, beverages, and other products. Glass bottles and jars provide a safe and inert environment, protecting the contents from contamination and spoilage. Vidro is also used in the packaging of pharmaceuticals and cosmetics, ensuring product quality and safety.

- Optics and Imaging

Vidro's optical properties, such as its ability to refract and transmit light, make it essential for lenses, prisms, and other optical components. In photography, microscopy, and scientific research, vidro plays a crucial role in image formation and analysis. Advanced optical fibers made of vidro enable efficient data transmission in telecommunications and networking.

- Industrial and Scientific Applications

Beyond its traditional uses, vidro finds applications in various industries and scientific fields. Its resistance to heat and chemicals makes it suitable for laboratory glassware, such as beakers and test tubes. In the electronics industry, vidro is used as a substrate for printed circuit boards and display screens. Vidro's unique properties also contribute to its use in solar panels, fiber optics, and other advanced technologies.

In conclusion, the versatility of vidro and its wide-ranging applications are driven by its inherent properties and the ability to tailor its composition and characteristics through manufacturing processes. From windows that illuminate buildings to lenses that capture images, and from containers that preserve food to advanced technologies that drive innovation, vidro continues to play a vital role in shaping our world.

Historical significance

The historical significance of vidro, dating back to ancient Mesopotamia, underscores its profound cultural and technological impact throughout human history. The earliest known glass objects, crafted by skilled artisans in Mesopotamia around 3500 BC, showcased the ingenuity and creativity of ancient civilizations.

Over the centuries, the art of glassmaking spread from Mesopotamia to Egypt and other regions, with each culture contributing to the evolving techniques and applications of this versatile material. The Phoenicians, renowned for their maritime trade, played a pivotal role in disseminating glassmaking knowledge throughout the Mediterranean and beyond. By the Roman era, vidro had become an integral part of everyday life, used for a wide range of purposes, including tableware, vessels for storage and transportation, and decorative objects.

The rich cultural history of vidro is intertwined with its technological advancements. Alchemists and scientists throughout the ages experimented with different compositions and techniques, seeking to refine the properties and applications of this remarkable material. The development of clear and colorless glass, known as crystal, marked a significant milestone in the 15th century, opening up new possibilities for artistic expression and scientific inquiry.

Today, vidro continues to be a material of immense cultural and technological importance. Its unique combination of properties, including transparency, hardness, and recyclability, makes it indispensable for a vast array of applications, from windows and containers to optical devices and advanced technologies. Understanding the historical significance of vidro provides a deeper appreciation for its enduring value and the ingenuity of human innovation.

Environmental impact

Vidro, with its inherent recyclability and durability, plays a significant role in promoting environmental sustainability. By utilizing recycled vidro, manufacturers can reduce the extraction of raw materials, conserve natural resources, and minimize waste sent to landfills.

- Reduced resource consumption

Recycling vidro significantly reduces the need to extract virgin materials, such as silica and soda ash, which are essential components in glass production. This conservation of natural resources helps preserve the environment and minimizes the impact on ecosystems.

- Lower carbon footprint

The production of new glass products from recycled vidro requires less energy compared to using virgin materials. This reduced energy consumption leads to a lower carbon footprint, contributing to efforts to mitigate climate change.

- Diversion from landfills

Recycling vidro diverts a substantial amount of waste from landfills, reducing the environmental burden associated with waste disposal. Landfills can contaminate soil and water sources, and recycling helps minimize this impact.

- Durable and long-lasting

Vidro is a highly durable material that can withstand wear and tear, making it a long-lasting choice for various applications. Its durability reduces the need for frequent replacements, further contributing to resource conservation and waste reduction.

In conclusion, the environmental impact of vidro is significantly reduced through its recyclability and durability. By utilizing recycled vidro, manufacturers can conserve natural resources, minimize waste, and reduce greenhouse gas emissions. The durability of vidro also extends its lifespan, further contributing to sustainability efforts. As a result, vidro emerges as an environmentally friendly material that promotes a more sustainable and circular economy.

Frequently Asked Questions (FAQs) on Vidro

This section provides answers to some of the most common questions and misconceptions about vidro, offering a deeper understanding of this versatile material.

Question 1: Is vidro recyclable?

Answer: Yes, vidro is highly recyclable. Recycling vidro reduces the need to extract raw materials and conserves natural resources. It also diverts waste from landfills, promoting a circular economy and reducing the environmental impact.

Question 2: Is vidro heat-resistant?

Answer: Certain types of vidro, such as borosilicate glass, are known for their high thermal resistance. Borosilicate glass can withstand extreme temperature changes, making it suitable for applications such as laboratory glassware and oven-safe cookware.

In summary, vidro's recyclability and durability make it an environmentally friendly choice, while its heat-resistant properties expand its range of applications. Understanding these aspects helps appreciate the versatility and significance of vidro in various industries and contexts.

Vidro

Our exploration of vidro has revealed its multifaceted nature, encompassing a unique combination of properties and applications. Its transparency, hardness, brittleness, recyclability, and historical significance make it an essential material in various industries and aspects of our lives.

The sustainability of vidro is a notable advantage. Its recyclability reduces the consumption of natural resources and minimizes waste, contributing to a circular economy. Additionally, its durability ensures longevity, further reducing the need for frequent replacements. By embracing the use of recycled vidro, we can promote environmental preservation and a more sustainable future.

As we continue to advance technologically and strive for a greener planet, vidro will undoubtedly remain a vital material. Its versatility and adaptability position it to meet the evolving demands of our modern world. By harnessing the potential of vidro, we can create innovative solutions, foster sustainable practices, and shape a brighter future.

Detail Author:

- Name : Micaela O'Keefe

- Username : kailee04

- Email : ywaelchi@gmail.com

- Birthdate : 1982-02-01

- Address : 7676 Freeman Place Apt. 869 West Audrachester, ND 97314

- Phone : 1-678-944-2259

- Company : Streich, Lebsack and Tremblay

- Job : Percussion Instrument Repairer

- Bio : Unde id vero corporis culpa. In perferendis minus et sunt voluptatem. Qui quis tempora expedita hic tempore.

Socials

linkedin:

- url : https://linkedin.com/in/moshe.lang

- username : moshe.lang

- bio : Et maiores eum facilis natus magni doloribus.

- followers : 6426

- following : 1591

facebook:

- url : https://facebook.com/moshe_lang

- username : moshe_lang

- bio : Beatae harum tempora et consequuntur temporibus.

- followers : 6277

- following : 1372