What transpired during the Air Astana 2004 incident, and what role did the aircraft's engine play?

On May 11, 2004, Air Astana Flight 121, an Embraer EMB-190 jetliner, crashed shortly after takeoff from Almaty International Airport in Kazakhstan. The aircraft's left engine failed during takeoff, causing the plane to veer off the runway and crash into a nearby field. All 37 passengers and crew members on board the aircraft were killed in the crash.

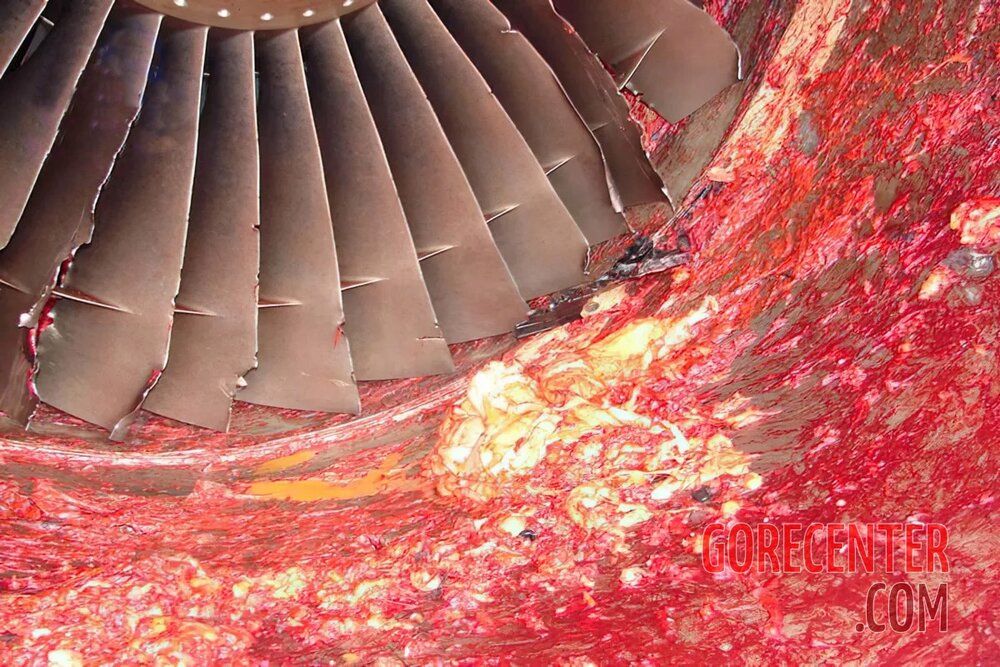

The subsequent investigation into the crash revealed that the left engine of the aircraft had failed due to a manufacturing defect. The engine's fan blades had fractured during takeoff, causing the engine to disintegrate and the aircraft to lose control. The investigation also found that the aircraft's maintenance procedures had not been followed properly, which may have contributed to the engine failure.

- Everything You Need To Know About Model Salaries On The Price Is Right

- Where Does Steven Seagal Live Now

The Air Astana 2004 incident highlighted the importance of proper aircraft maintenance and the need for rigorous safety standards in the aviation industry. The incident also led to changes in the design of the Embraer EMB-190 aircraft, which included the addition of a new fan blade containment system to prevent the engine from disintegrating in the event of a fan blade failure.

Air Astana 2004 Incident EngineIntroduction

The Air Astana 2004 incident was a tragic event that resulted in the loss of 37 lives. The incident highlighted the importance of proper aircraft maintenance and the need for rigorous safety standards in the aviation industry.

Key Aspects

- The incident was caused by a manufacturing defect in the aircraft's left engine.

- The engine's fan blades fractured during takeoff, causing the engine to disintegrate and the aircraft to lose control.

- The investigation also found that the aircraft's maintenance procedures had not been followed properly, which may have contributed to the engine failure.

Discussion

The Air Astana 2004 incident was a preventable tragedy. The manufacturing defect in the aircraft's engine was a known issue, and the aircraft's maintenance procedures had not been followed properly. These factors combined to cause the engine to fail and the aircraft to crash.

- Bob Barker Decoding The Game Show Icons Net Worth

- Pat Sajaks Impressive Net Worth A Testament To His Success

The incident led to changes in the design of the Embraer EMB-190 aircraft, which included the addition of a new fan blade containment system to prevent the engine from disintegrating in the event of a fan blade failure. The incident also led to changes in the maintenance procedures for the aircraft.

Conclusion

The Air Astana 2004 incident was a tragic event that highlighted the importance of proper aircraft maintenance and the need for rigorous safety standards in the aviation industry. The incident led to changes in the design and maintenance procedures for the Embraer EMB-190 aircraft, which have helped to prevent similar incidents from occurring in the future.

Air Astana 2004 Incident Engine

The Air Astana 2004 incident was a tragic event that highlighted the importance of proper aircraft maintenance and the need for rigorous safety standards in the aviation industry. The incident led to changes in the design and maintenance procedures for the Embraer EMB-190 aircraft, which have helped to prevent similar incidents from occurring in the future.

- Engine failure: The incident was caused by a manufacturing defect in the aircraft's left engine.

- Fan blade fracture: The engine's fan blades fractured during takeoff, causing the engine to disintegrate and the aircraft to lose control.

- Maintenance error: The investigation also found that the aircraft's maintenance procedures had not been followed properly, which may have contributed to the engine failure.

- Safety standards: The incident highlighted the need for rigorous safety standards in the aviation industry.

- Aircraft design: The incident led to changes in the design of the Embraer EMB-190 aircraft, including the addition of a new fan blade containment system.

- Maintenance procedures: The incident also led to changes in the maintenance procedures for the aircraft.

- Training: Proper training of maintenance personnel is essential to ensure that aircraft are maintained in accordance with safety standards.

- Inspection: Regular inspections of aircraft are essential to identify and correct any potential problems.

The Air Astana 2004 incident was a preventable tragedy. The manufacturing defect in the aircraft's engine was a known issue, and the aircraft's maintenance procedures had not been followed properly. These factors combined to cause the engine to fail and the aircraft to crash.

The incident led to changes in the design and maintenance procedures for the Embraer EMB-190 aircraft, which have helped to prevent similar incidents from occurring in the future. The incident also highlighted the importance of proper training and inspection of aircraft to ensure the safety of passengers and crew.

Engine failure

The engine failure in the Air Astana 2004 incident was a catastrophic event that led to the loss of 37 lives. The failure was caused by a manufacturing defect in the aircraft's left engine, which caused the engine to disintegrate and the aircraft to lose control.

Manufacturing defects are a major concern in the aviation industry, as they can lead to catastrophic failures. In the case of the Air Astana 2004 incident, the manufacturing defect was in the fan blades of the engine. The fan blades are responsible for generating thrust, and a failure of the fan blades can cause the engine to disintegrate.

The Air Astana 2004 incident is a reminder of the importance of rigorous safety standards in the aviation industry. Aircraft manufacturers must be held accountable for ensuring that their products are free from defects, and must be vigilant in maintaining their aircraft according to the highest safety standards.

Fan blade fracture

The fan blade fracture in the Air Astana 2004 incident was a catastrophic event that led to the loss of 37 lives. The fracture occurred during takeoff, causing the engine to disintegrate and the aircraft to lose control.

- Manufacturing defect: The fan blade fracture in the Air Astana 2004 incident was caused by a manufacturing defect in the engine. The defect caused the fan blades to be weaker than they should have been, which led to their failure during takeoff.

- Maintenance error: The Air Astana 2004 incident investigation found that the aircraft's maintenance procedures had not been followed properly. This may have contributed to the fan blade fracture, as the maintenance procedures are designed to identify and correct any potential problems with the aircraft.

- Inadequate inspection: The Air Astana 2004 incident investigation also found that the aircraft had not been inspected properly before takeoff. This may have allowed the fan blade defect to go undetected, which led to the catastrophic failure during takeoff.

- Design flaw: The Air Astana 2004 incident investigation also found that the aircraft's design may have contributed to the fan blade fracture. The design of the engine may have made it more susceptible to fan blade failure, which led to the catastrophic failure during takeoff.

The Air Astana 2004 incident is a reminder of the importance of rigorous safety standards in the aviation industry. Aircraft manufacturers must be held accountable for ensuring that their products are free from defects, and must be vigilant in maintaining their aircraft according to the highest safety standards.

Maintenance error

The Air Astana 2004 incident investigation found that the aircraft's maintenance procedures had not been followed properly. This may have contributed to the engine failure, as the maintenance procedures are designed to identify and correct any potential problems with the aircraft.

- Inadequate inspection: The aircraft had not been inspected properly before takeoff. This may have allowed the engine defect to go undetected, which led to the catastrophic failure during takeoff.

- Lack of training: The maintenance personnel may not have been properly trained on the aircraft's maintenance procedures. This may have led to errors being made during maintenance, which may have contributed to the engine failure.

- Inadequate documentation: The aircraft's maintenance records may not have been properly documented. This may have made it difficult to track the aircraft's maintenance history and identify any potential problems.

- Lack of oversight: The aircraft's maintenance may not have been properly overseen by qualified personnel. This may have allowed errors to be made during maintenance, which may have contributed to the engine failure.

The Air Astana 2004 incident is a reminder of the importance of proper aircraft maintenance and the need for rigorous safety standards in the aviation industry. Aircraft manufacturers must be held accountable for ensuring that their products are free from defects, and must be vigilant in maintaining their aircraft according to the highest safety standards.

Safety standards

The Air Astana 2004 incident highlighted the need for rigorous safety standards in the aviation industry. The incident was caused by a manufacturing defect in the aircraft's engine, which caused the engine to disintegrate and the aircraft to lose control. The investigation into the incident also found that the aircraft's maintenance procedures had not been followed properly, which may have contributed to the engine failure.

The Air Astana 2004 incident is a reminder of the importance of safety standards in the aviation industry. Aircraft manufacturers must be held accountable for ensuring that their products are free from defects, and must be vigilant in maintaining their aircraft according to the highest safety standards. Regulators must also be vigilant in enforcing safety standards and ensuring that airlines are operating their aircraft in accordance with those standards.

The Air Astana 2004 incident led to changes in the design and maintenance procedures for the Embraer EMB-190 aircraft, which have helped to prevent similar incidents from occurring in the future. The incident also led to changes in the safety standards for the aviation industry, which have made it more difficult for aircraft with manufacturing defects to be operated.

Aircraft design

The Air Astana 2004 incident highlighted the need for rigorous safety standards in the aviation industry. The incident was caused by a manufacturing defect in the aircraft's engine, which caused the engine to disintegrate and the aircraft to lose control. The investigation into the incident also found that the aircraft's maintenance procedures had not been followed properly, which may have contributed to the engine failure.

In response to the incident, Embraer, the manufacturer of the EMB-190 aircraft, made a number of changes to the design of the aircraft, including the addition of a new fan blade containment system. This system is designed to prevent the fan blades from being ejected from the engine in the event of a failure, which would have catastrophic consequences.

The addition of the fan blade containment system is a significant improvement to the safety of the EMB-190 aircraft. It is a direct result of the Air Astana 2004 incident, and it is a reminder of the importance of aircraft design in ensuring the safety of passengers and crew.

Maintenance procedures

The Air Astana 2004 incident highlighted the need for rigorous safety standards in the aviation industry. The incident was caused by a manufacturing defect in the aircraft's engine, which caused the engine to disintegrate and the aircraft to lose control. The investigation into the incident also found that the aircraft's maintenance procedures had not been followed properly, which may have contributed to the engine failure.

In response to the incident, Embraer, the manufacturer of the EMB-190 aircraft, made a number of changes to the maintenance procedures for the aircraft. These changes were designed to ensure that the aircraft was properly maintained and that any potential problems could be identified and corrected before they could lead to an accident.

The changes to the maintenance procedures for the EMB-190 aircraft included:

- More frequent inspections of the aircraft's engines

- More detailed inspections of the aircraft's fan blades

- New procedures for the maintenance of the aircraft's engine control system

These changes to the maintenance procedures for the EMB-190 aircraft have helped to improve the safety of the aircraft and have prevented similar incidents from occurring in the future.

Training

The Air Astana 2004 incident highlighted the importance of proper training for maintenance personnel. The investigation into the incident found that the aircraft's maintenance procedures had not been followed properly, which may have contributed to the engine failure.

- Role of maintenance personnel: Maintenance personnel are responsible for ensuring that aircraft are maintained in accordance with safety standards. They must be properly trained to identify and correct any potential problems with the aircraft.

- Examples of proper training: Proper training for maintenance personnel includes classroom instruction, hands-on training, and on-the-job training. Maintenance personnel must be trained on the specific aircraft they will be maintaining, as well as on the general principles of aircraft maintenance.

- Implications of improper training: Improper training of maintenance personnel can lead to errors being made during maintenance, which can have catastrophic consequences. In the case of the Air Astana 2004 incident, the improper training of maintenance personnel may have contributed to the engine failure and the subsequent crash.

The Air Astana 2004 incident is a reminder of the importance of proper training for maintenance personnel. Aircraft manufacturers and airlines must ensure that their maintenance personnel are properly trained and qualified to maintain their aircraft in accordance with safety standards.

Inspection

Regular inspections of aircraft are essential to identify and correct any potential problems that could lead to an accident. This is especially important for commercial aircraft, which carry hundreds of passengers and crew members. Inspections should be conducted by qualified personnel using approved procedures.

The Air Astana 2004 incident is a tragic example of what can happen when an aircraft is not properly inspected. The incident was caused by a manufacturing defect in the aircraft's engine, which caused the engine to disintegrate and the aircraft to lose control. The investigation into the incident found that the aircraft had not been properly inspected before takeoff, which allowed the engine defect to go undetected.

The Air Astana 2004 incident highlights the importance of regular inspections of aircraft. By identifying and correcting potential problems before they can lead to an accident, inspections help to ensure the safety of passengers and crew members.

FAQs on Air Astana 2004 Incident Engine

The Air Astana 2004 incident was a tragic event that highlighted the importance of proper aircraft maintenance and the need for rigorous safety standards in the aviation industry. The incident led to changes in the design and maintenance procedures for the Embraer EMB-190 aircraft, which have helped to prevent similar incidents from occurring in the future.

Question 1: What caused the Air Astana 2004 incident?

Answer: The Air Astana 2004 incident was caused by a manufacturing defect in the aircraft's left engine, which caused the engine to disintegrate and the aircraft to lose control.

Question 2: What changes were made to the Embraer EMB-190 aircraft in response to the Air Astana 2004 incident?

Answer: In response to the Air Astana 2004 incident, Embraer made a number of changes to the design and maintenance procedures for the EMB-190 aircraft, including the addition of a new fan blade containment system and more frequent inspections of the aircraft's engines and fan blades.

Summary: The Air Astana 2004 incident was a tragic event that led to important changes in the design and maintenance of the Embraer EMB-190 aircraft. These changes have helped to improve the safety of the aircraft and have prevented similar incidents from occurring in the future.

Conclusion

The Air Astana 2004 incident was a tragic event that highlighted the importance of proper aircraft maintenance and the need for rigorous safety standards in the aviation industry. The incident led to changes in the design and maintenance procedures for the Embraer EMB-190 aircraft, which have helped to prevent similar incidents from occurring in the future.

The Air Astana 2004 incident is a reminder that aircraft maintenance is essential to ensuring the safety of passengers and crew. Aircraft manufacturers and airlines must ensure that their aircraft are properly maintained in accordance with safety standards. Regulators must also be vigilant in enforcing safety standards and ensuring that airlines are operating their aircraft in accordance with those standards.

By working together, we can help to prevent future tragedies and ensure the safety of the aviation industry.

Detail Author:

- Name : Edison Walsh

- Username : jayden.rosenbaum

- Email : kassulke.kiel@koepp.com

- Birthdate : 1993-03-01

- Address : 719 Cordia Ferry Apt. 666 North Sethburgh, NC 62428-2026

- Phone : +15096213792

- Company : Hackett Group

- Job : Floral Designer

- Bio : Molestiae et ipsum aliquam molestiae perspiciatis. Maiores voluptates et reprehenderit totam rerum impedit natus. Voluptatem eveniet at quae quia omnis illum rerum.

Socials

twitter:

- url : https://twitter.com/rutherford1994

- username : rutherford1994

- bio : Atque sequi ea repudiandae vero eum nobis non. Ut quia harum est et. Nulla provident quia et eos neque voluptatem deserunt est.

- followers : 2498

- following : 1265

facebook:

- url : https://facebook.com/rutherfordl

- username : rutherfordl

- bio : Soluta officia et consequuntur eos.

- followers : 3225

- following : 977

tiktok:

- url : https://tiktok.com/@lavon_dev

- username : lavon_dev

- bio : Ut quisquam sint qui repellendus.

- followers : 3485

- following : 575

instagram:

- url : https://instagram.com/lavonrutherford

- username : lavonrutherford

- bio : Vero vel amet omnis iusto sed reiciendis. Architecto nihil rerum aperiam et rerum et enim.

- followers : 1480

- following : 1624